I may have mentioned in passing my fat arsed steel cutter and plans to point it in a watery direction.

In aid of these plans, I'm taking my late 1980s Westerbeke W-52 out for inspection and potential rebuild. It's only got 1300 hours on it, but as I could put on 1,000 hrs./year for five years, it's reasonable to "refresh it" as much as possible.

Trouble is that the Internet was but a baby when this engine was popular, and there's a dearth of information on it. Luckily, I have a parts lists, a superseded parts list, and a very nice shop manual. I am having work done this winter at a general diesel (not marine) place that does trucks and train diesels. I estimate maybe 10 hours of work by a decent rebuilder are required.

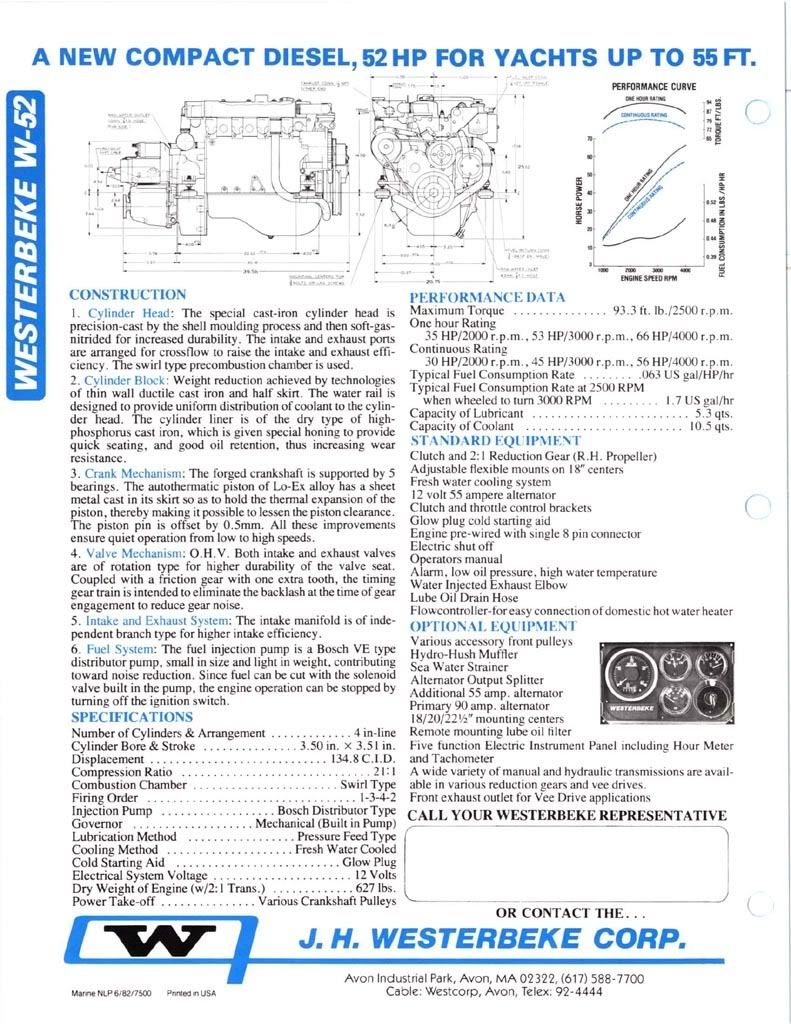

Here's the rub: I have found that this Westerbeke is a Mazda diesel used in B2000 and B2200 pickups from the early '80s. I have also learned that Mazda built diesels for Perkins to Perkins specs in Japan. I believe my Westerbeke is essentially the Mazda S2 or perhaps R2 engine (134.8 cu. in is the same as 2200 cc displacement.) I also think this engine is the same block as the Perkins 4.135 (first pic), and therefore the Westerbeke W-52. (second pic). The W-52 spec sheet is the last picture.

![Image]()

![Image]()

![Image]()

So, my point is this: Westerbeke charges an arm, a leg and a testicle for parts. Might I not do better via Mazda or even Perkins, if I can prove that the Westerbeke is the marinized (aka add pumps and zincs) version of the Mazda S2 diesel for pickups, which is also the Perkins 4.135, of which I bet more were made than the Westerbeke...

EDIT: If I'm right that the Westie/Mazda/Perkins are the same block, then it was also used in early '80s Ford Rangers. The cylinder bore on the W-52 is 3.50" x 3.51"

Your advice or insights are valued.

In aid of these plans, I'm taking my late 1980s Westerbeke W-52 out for inspection and potential rebuild. It's only got 1300 hours on it, but as I could put on 1,000 hrs./year for five years, it's reasonable to "refresh it" as much as possible.

Trouble is that the Internet was but a baby when this engine was popular, and there's a dearth of information on it. Luckily, I have a parts lists, a superseded parts list, and a very nice shop manual. I am having work done this winter at a general diesel (not marine) place that does trucks and train diesels. I estimate maybe 10 hours of work by a decent rebuilder are required.

Here's the rub: I have found that this Westerbeke is a Mazda diesel used in B2000 and B2200 pickups from the early '80s. I have also learned that Mazda built diesels for Perkins to Perkins specs in Japan. I believe my Westerbeke is essentially the Mazda S2 or perhaps R2 engine (134.8 cu. in is the same as 2200 cc displacement.) I also think this engine is the same block as the Perkins 4.135 (first pic), and therefore the Westerbeke W-52. (second pic). The W-52 spec sheet is the last picture.

So, my point is this: Westerbeke charges an arm, a leg and a testicle for parts. Might I not do better via Mazda or even Perkins, if I can prove that the Westerbeke is the marinized (aka add pumps and zincs) version of the Mazda S2 diesel for pickups, which is also the Perkins 4.135, of which I bet more were made than the Westerbeke...

EDIT: If I'm right that the Westie/Mazda/Perkins are the same block, then it was also used in early '80s Ford Rangers. The cylinder bore on the W-52 is 3.50" x 3.51"

Your advice or insights are valued.