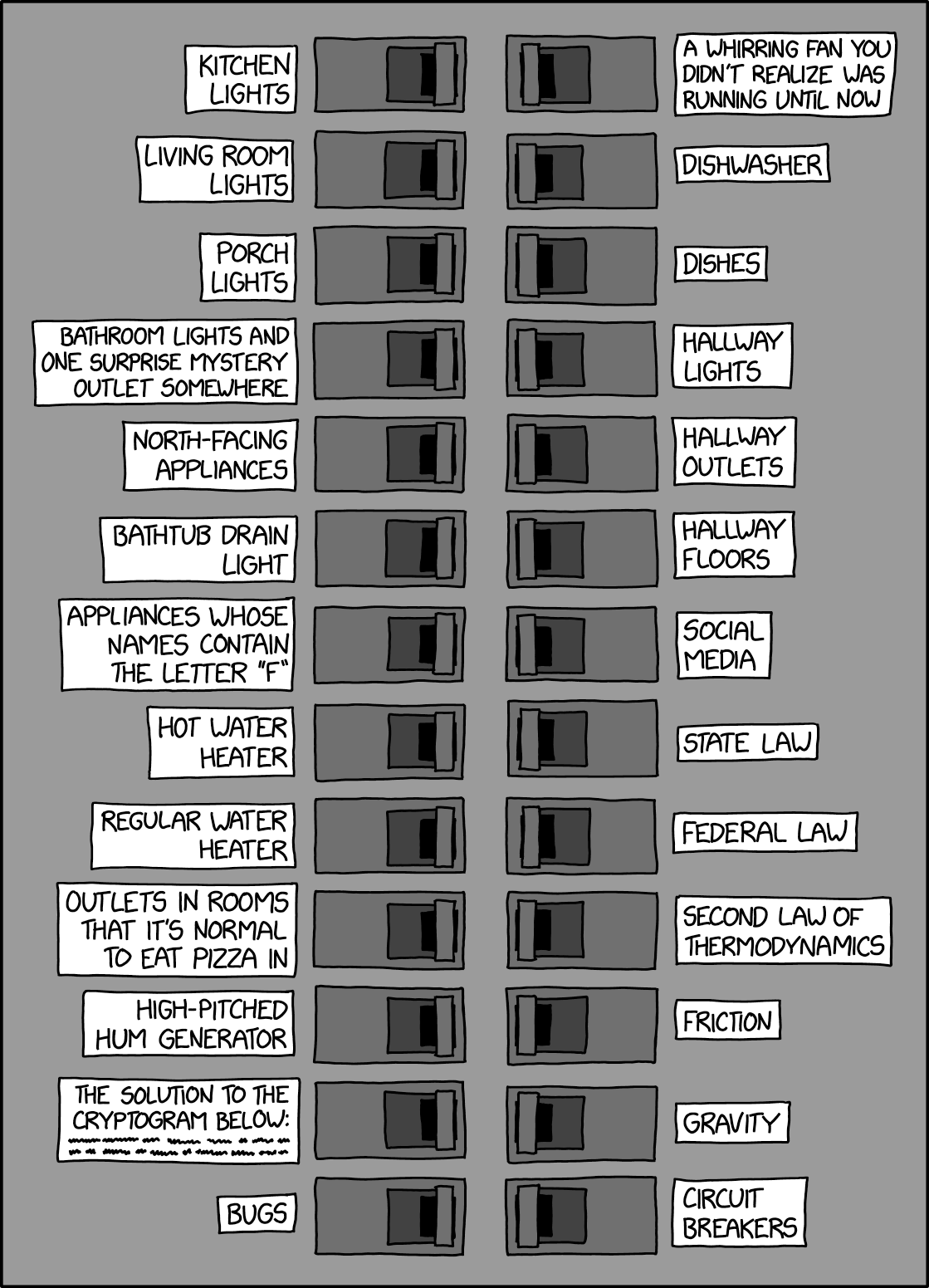

Anyone who has bought a boat that had several PO's has probably seen an electrical panel with tape and hand written descriptions over the original labeling. If the PO's were crazy/lazy/inept, the panels are often functionally similar to this:

![Image]()

I understand your pain. Attached are my before and almost done after pictures. I bet my rats nest would have given yours a run for the money. I removed 4 large kitchen sized garbage bags literally stuffed full of old cables and wiring. And the pain of seeing/fixing the way POs ran wires. I have multiple factory installed conduits running from port to starboard. One conduit was almost empty (so plenty of run to run wires) but POs in past just zip tied wires to the outside of the conduit rather than run the wires through the conduit. All in all the boat was a mess and dangerous with heavy gauge (2/0) wires unfused.It's been two years of ownership and I have not opened the panel.

I'm afraid to after opening the instrument pod and seeing the world's record rat's nest, discovering that battery connections are mislabeled, the mast wiring is mislabeled, and having to rewire parts of the boat.